Mākēneki vs Pneumatic Workholding for thin Sheet Aluminum

Mea kākau: PFT, Shenzhen

ʻĀpana

ʻO ka mīkini pololei o ka alumini pepa lahilahi (<3mm) ke alo nei i nā luʻina hana nui. Hoʻohālikelike kēia haʻawina i nā ʻōnaehana hoʻopili magnetic a me ka pneumatic ma lalo o nā kūlana milling CNC. ʻO nā ʻāpana hoʻāʻo e pili ana i ka hoʻopaʻa ʻana i ka ikaika, ke kūpaʻa wela (20°C–80°C), ka haʻalulu haʻalulu, a me ka distortion o ka ʻili. Ua mālama ʻia nā ʻāpana ʻūhā pneumatic i 0.02mm palahalaha no nā ʻāpana 0.8mm akā makemake ʻia nā ʻili i hoʻopaʻa ʻia. Ua hiki i nā chucks electromagnetic ke komo i ka 5-axis a ho'ēmi i ka manawa hoʻonohonoho e 60%, akā naʻe, ua hoʻoulu ʻia nā au eddy i ka hoʻomehana kūloko ma mua o 45 ° C ma 15,000 RPM. Hōʻike nā hualoaʻa i nā ʻōnaehana vacuum e hoʻopaneʻe i ka hoʻopau ʻana o ka ʻili no nā pepa> 0.5mm, ʻoiai nā hoʻonā magnetic e hoʻomaikaʻi i ka maʻalahi no ka prototyping wikiwiki. Loaʻa nā palena i nā ala hybrid ʻaʻole i hoʻāʻo ʻia a me nā mea ʻē aʻe i hoʻopaʻa ʻia.

1 Hoolauna

ʻO nā ʻoihana mana o nā ʻāpana alumini lahilahi mai ka aerospace (nā ʻili fuselage) a i nā mea uila (hana wela). Eia nō naʻe, hōʻike ʻia nā noiʻi ʻoihana 2025 he 42% o nā hemahema pololei mai ka neʻe ʻana o ka mea hana i ka wā o ka mīkini. Hoʻololi pinepine ʻia nā ʻāpana mīkini maʻamau i nā ʻāpana sub-1mm, ʻoiai ʻaʻole i paʻa nā ʻano hana lipine. Hoʻonui kēia haʻawina i ʻelua mau hoʻonā holomua: electromagnetic chucks leveraging remanence control technology and pneumatic system with multi-zone vacuum control.

2 Hoʻoponopono

2.1 Hoʻolālā Hoʻokolohua

-

Mea Hana: 6061-T6 mau pepa alumini (0.5mm/0.8mm/1.2mm)

-

Mea lako:

-

Magnetic: GROB 4-axis electromagnetic chuck (0.8T kahua ikaika)

-

Pneumatic: ʻO ka pā ʻūhā SCHUNK me 36-zone manifold

-

-

Ka ho'āʻo: ʻili palahalaha (laser interferometer), thermal imaging (FLIR T540), vibration analysis (3-axis accelerometers)

2.2 Nā Kūlana Hoʻāʻo

-

Paʻa Paʻa: E ana i ka hoʻokaʻawale ʻana ma lalo o ka ikaika ʻaoʻao 5N

-

Paʻa Paʻipaʻi Thermal: E hoʻopaʻa i nā ʻanuʻu wela i ka wā o ka milling slot (Ø6mm end mill, 12,000 RPM)

-

ʻOkoʻa ikaika: E hoʻopaʻa i ka amplitude vibration ma nā alapine resonant (500–3000 Hz)

3 Nā hualoaʻa a me ka nānā ʻana

3.1 Hoʻokō Paʻi

| ʻĀpana | Pneumatic (0.8mm) | Mākēneki (0.8mm) |

|---|---|---|

| Avg. Hoʻopiʻi | 0.02mm | 0.15mm |

| Ka manawa hoʻonohonoho | 8.5 min | 3.2 min |

| Piʻi ʻana o ka Maha | 22°C | 48°C |

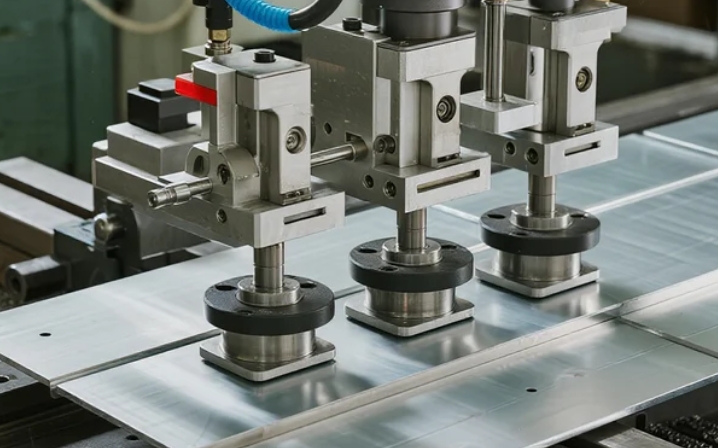

Kiʻi 1: Ua mālama ʻia nā ʻōnaehana ʻūhā <5μm i ka hoʻololi ʻana o ka ʻili i ka wā o ka wili ʻana i ke alo, ʻoiai ua hōʻike ʻia ka hoʻopaʻa ʻana o ka magnetic he 0.12mm ka hāpai ʻana ma muli o ka hoʻonui wela.

3.2 Nā hiʻohiʻona haʻalulu

Ua hoʻopau ʻia nā huila pneumatic i nā harmonics e 15dB ma 2,200Hz - koʻikoʻi no nā hana hoʻopau maikaʻi. Ua hōʻike ʻia ka hana hana magneti he 40% kiʻekiʻe aʻe ma nā alapine hoʻopili mea hana.

4 Kūkākūkā

4.1 Nā Kūʻai ʻenehana

-

Pōmaikaʻi Pneumatic: ʻOi aku ka maikaʻi o ka wela a me ka vibration damping suit i nā noi hoʻomanawanui kiʻekiʻe e like me nā kumu ʻāpana optical.

-

ʻO Magnetic Edge: Kākoʻo ka hoʻonohonoho hou ʻana i nā kaiapuni hale kūʻai hana e lawelawe ana i nā ʻāpana like ʻole.

Ka palena: Hoʻokaʻawale ʻia nā hoʻāʻo ʻana i nā lau a i ʻole ka ʻaila kahi e hāʻule ai ka pono o ka vacuum >70%. Pono nā haʻina Hybrid i ke aʻo ʻana e hiki mai ana.

5 Ka hopena

No ka mīkini pepa alumini lahilahi:

-

Hāʻawi ka paʻahana pneumatic i ka pololei kiʻekiʻe no ka mānoanoa> 0.5mm me nā ʻaoʻao i hoʻopaʻa ʻole ʻia.

-

Hoʻemi nā ʻōnaehana magnetic i ka manawa ʻoki ʻole e 60% akā makemake i nā hoʻolālā coolant no ka hoʻokele wela

-

ʻO ke koho maikaʻi loa e pili ana i nā pono o ka throughput me nā koi hoʻomanawanui

Pono nā noiʻi e hiki mai ana e ʻimi i nā ʻāpana hybrid adaptive a me nā hoʻolālā electromagnet haʻahaʻa.

Ka manawa hoʻouna: Iulai-24-2025